Quality Control

An essential step to ensure that your product meets your expectations

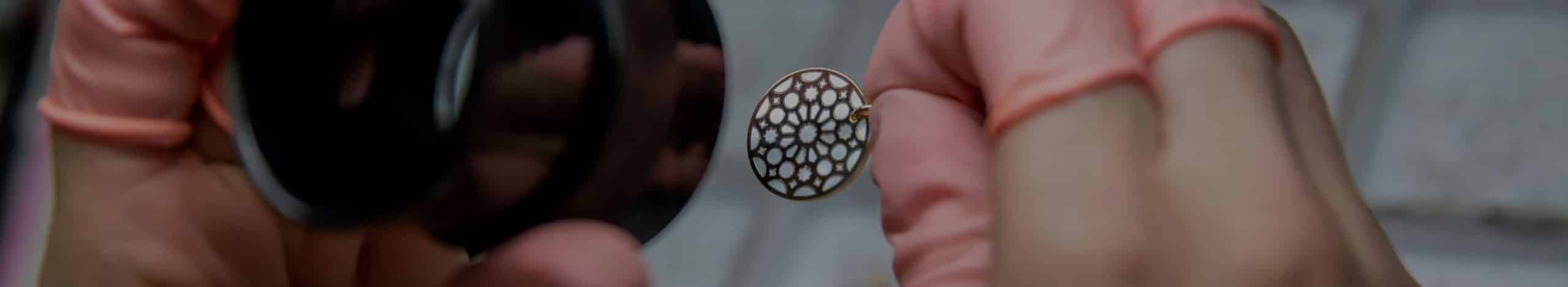

The quality control department has a manager who coordinates the activities of a team of highly experienced inspectors. A piece may pass through the hands of several testers, as they must be totally convinced that the product fully meets the client’s specifications.

This means that you have to be very demanding and pay close attention to every detail.

Pichard-Balme is committed to excellence, the goal of this service is to meet demand and provide answers to customers.

For this purpose, our testing laboratory is equipped with natural white lights and a high-powered digital microscope to detect the slightest defect.

Clear, clean & precise

Our laboratory tests

We have a well-equipped laboratory to carry out tests on prototypes, pre-series, at the request of the client or the project manager.

It is a real desire on our part to test our products internally because we want to find ever more innovative solutions in order to guarantee a product quality that strives towards excellence.

In addition, our teams are trained in gemmological quality control and have specialised equipment such as a refractometer, a density control balance and a UV chamber.

We also carry out more “classic” tests such as:

- Resistance to synthetic sweat

- Thermal shock

- Resistance to solvents

- Resistance to cosmetics and detergents

- Wear test

- Sellotape adhesion

- Resistance to falls

The stages

The product journey

1

2

3

4

5

6

The little extra

The Pichard-Balme Guarantee

As a reminder, each of our pieces rigorously respects the specifications of the client, our workshops’ desire for excellence, as well as numerous regulations. These are varied and depend on the geographical area, the metal selected, etc.

At Pichard-Balme, we have a fischerscope which allows us to check the titles of our products, and in particular their various components.

More precisely, we are authorised under article 523b of the general tax code to confirm the guarantee of the title by marking or laser of the title stamps.

We therefore have a set of specifications set out in accordance with Article 275 bis C of Annex II of the tax code as part of the authorisation agreement as a manufacturer which has been concluded between the Pays de la Loire regional directorate of customs and indirect rights and our workshops.