Innovation

Laser decoration, and there was light

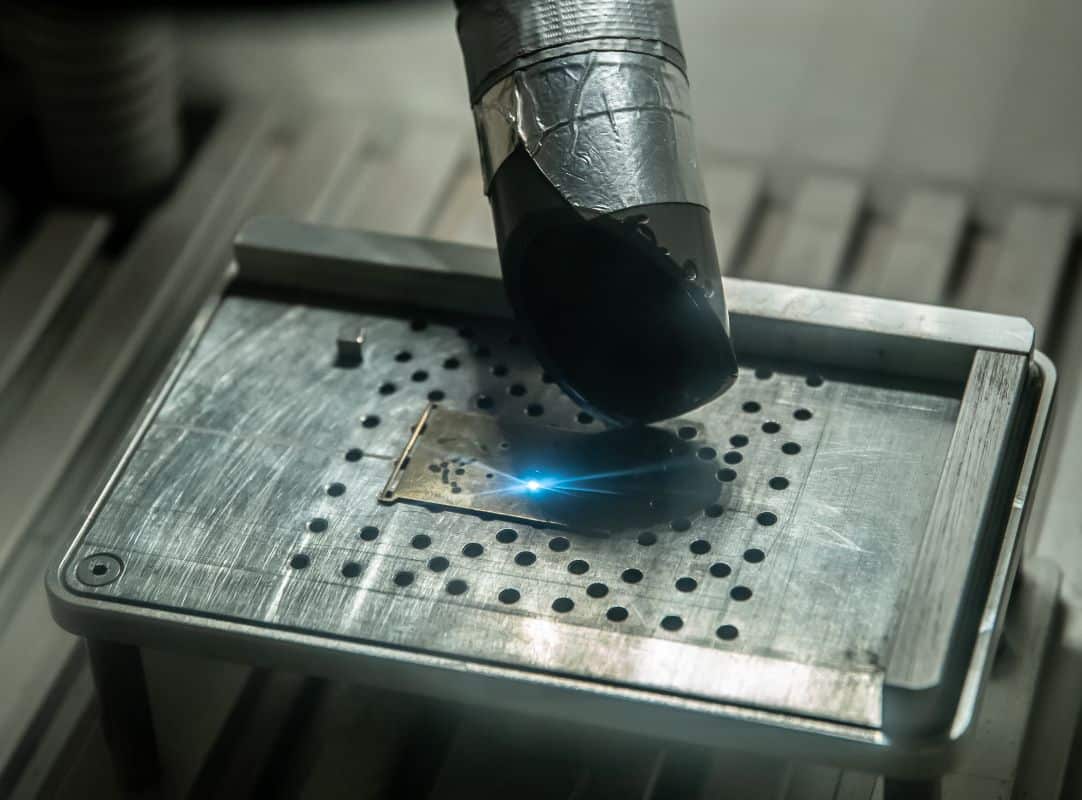

Laser decoration is a new feature at Pichard-Balme. We opened this workshop at the beginning of 2021 with the aim of permanently personalising our exceptional pieces. The aim is to use a laser beam to inscribe unalterable characters on a product or to change its colouring. The role of the laser operator is to prepare the computer files, i.e. the engraving paths, to apply the precision techniques related to metalworking and to supervise the various machines.

The laser sends out a light beam in such a way as to physically sublimate the material. This sublimation consists in making the beam pass from a solid state to a gaseous state without passing through the liquid stage. In practice, the light beam modifies the metal to create a raised or recessed shape, unlike machining, which uses a cutting tool. There are several types of laser engraving:

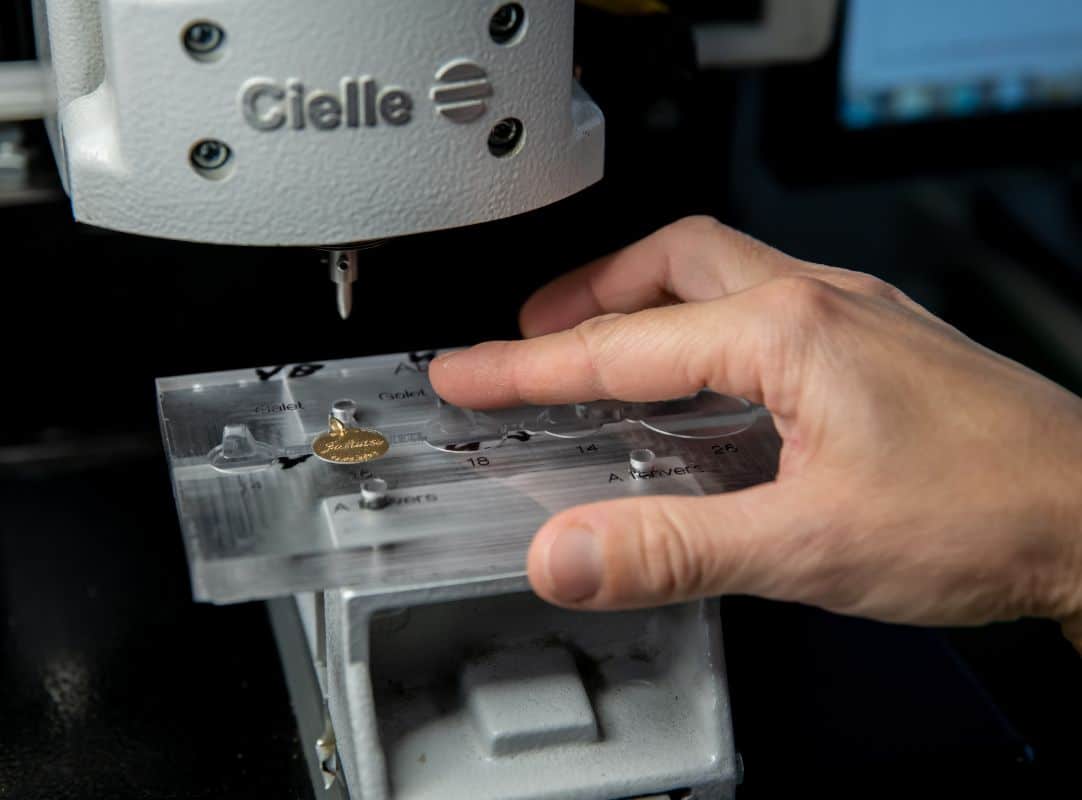

We have state hallmarks: a state hallmark engraving is the proof that the tax administration of the Guarantee records the hallmark of each goldsmith, its name and its registration number in order to guarantee its validity and uniqueness.

At Ateliers Pichard Balme, the eagle head is for gold and the minerva for silver.

This guarantee allows us to affirm that the precious metals meet a precise legislative title.

Modernisation

Design version 2.0

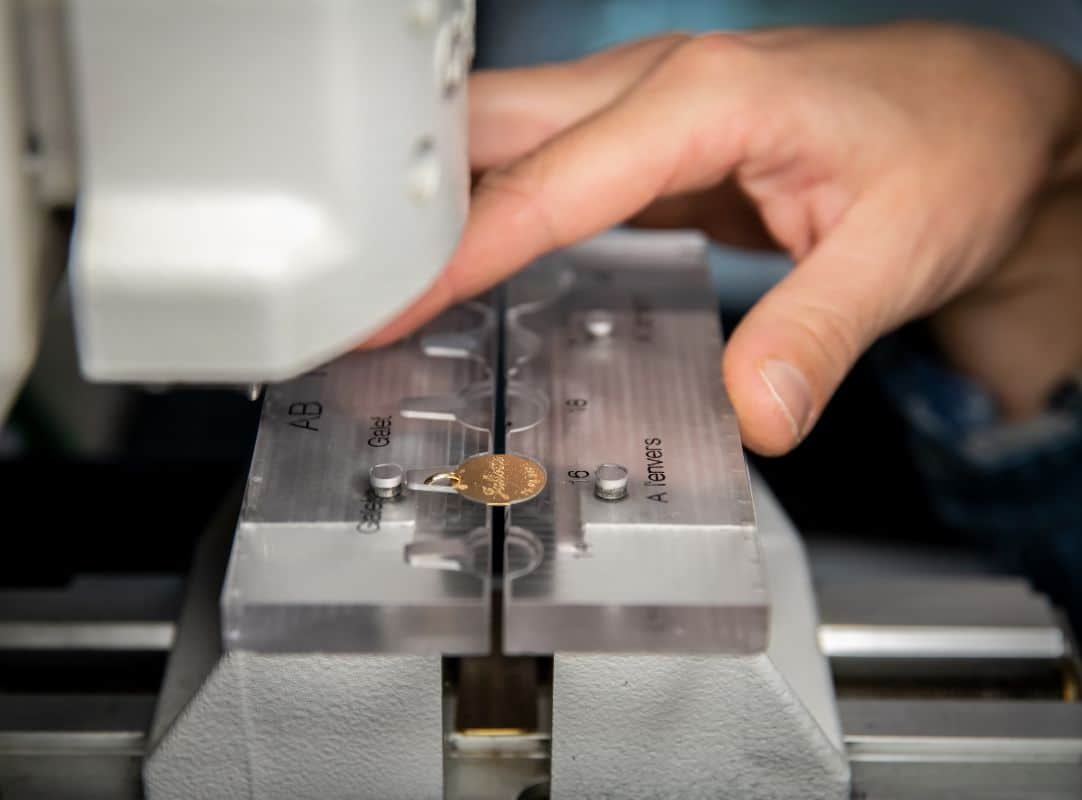

To carry out laser decoration on our precious metals, our operators first receive a set of parts, which contains the manufacturing order of the range and the nomenclature as well as the source file containing a list of numbers to be engraved, such as customer numbers for example. Their task is to enter all this information into the digital control system of the machines. Then they have to check that the cutting or engraving is done correctly. We have several machines with large capacities: four axes that allow us to make engravings on cylinders (inside and outside) and that can operate over a long period of time (a whole night for example).

Laser engraving

A futuristic & age-old vision

Our laser operators come from the traditional jewellery industry. They have been trained in our workshops. They therefore have a meticulous and professional eye for the aesthetics of laser decorations. They know the materials perfectly and how to work them well to obtain the best possible result.

The major advantage of laser engraving is its precision. The risk of damaging or warping the material is therefore extremely low. Moreover, the graphics produced with the laser allow the initial shape of the object to be preserved.

The laser allows objects to be sublimated and sometimes complements traditional material texturing techniques (guilloche, terlage, soleilage).