Resin

Colouring pieces of different media

The process of applying precious lacquer makes it possible to colour parts on different surfaces.

This colouring is considered to be a thermosetting liquid polymer consisting of different components. Furthermore, it is possible to incorporate pigments.

The role of the production operator is therefore to prepare the different colour compositions and to apply the solution to the parts.

Step 1

Choosing the right pigments to create the colour

The first step is to search for and create the different mixtures. The operator receives a colour reference from the customer. The operator has to organise themselves in order to obtain the desired result. To create a colour, several ingredients must be selected. Then they have to be mixed in order to obtain the colour requested by the customer. The operator acquires knowledge and expertise in this area over time.

Step 2

A numbers game

The second step is to add the right amount of pigment to the planetary mixer. This device dilutes the air bubbles and homogenises the mixture. Finally, the catalyst must be added to the mixture. This product is essential because it enables the base to harden.

Obtaining the right colour can take anywhere from an hour to several days of research. It is possible to make a large number of compositions before finding the one that is best suited. It is therefore through testing that the operator can measure the right amount of chemicals needed for the preparation.

Step 3

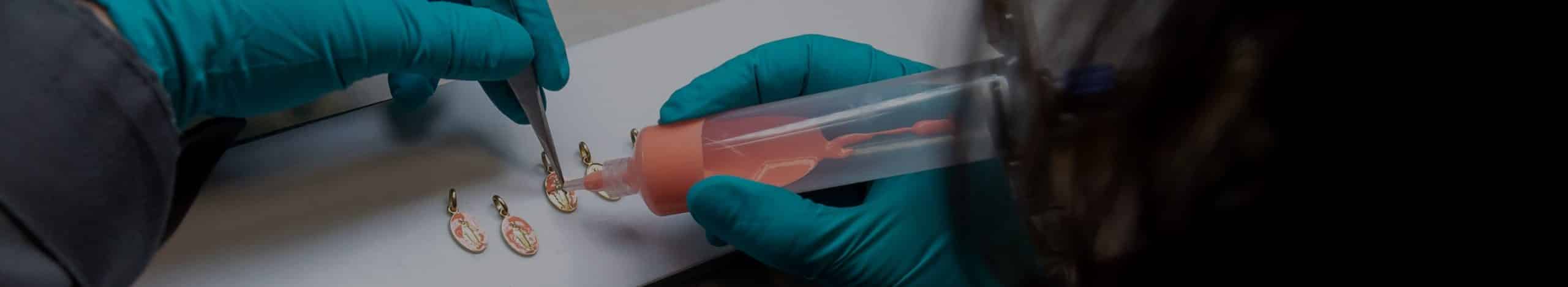

Colouring parts with lacquer

The operator’s third task is to apply the lacquer to parts of different substrates with the mixtures made earlier. To do this, the syringe must be filled with the formula. There are different flow rates depending on the surface to be coated. To ensure that the expected result is achieved, the operator relies on a model and on the instructions in the production order.

Finally, the deposited part must be placed in an oven to catalyse it and give it an optimal result.

Our workshop masters the 2 main techniques of lacquering from syringe deposit:

- Surface coating

- Polishing deposit

We know how to advise our customers according to their expectations.